Mica is a versatile mineral widely used in various industries, including electronics, construction, cosmetics, and more. Its unique properties such as heat resistance, electrical insulation, and durability make it indispensable in modern manufacturing processes. In this article, we will explore the 5 common types of mica, their uses, and the different forms in which they are supplied, with a focus on AUKI MICA, a high-end supplier of mica sheets and insulating materials based in Hubei Province, China.

What is Mica?

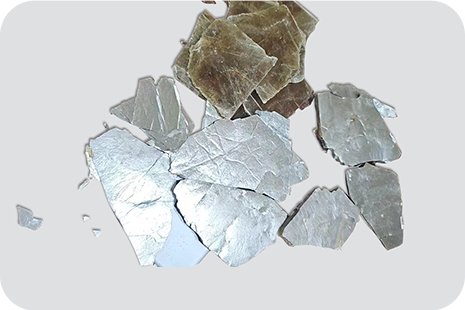

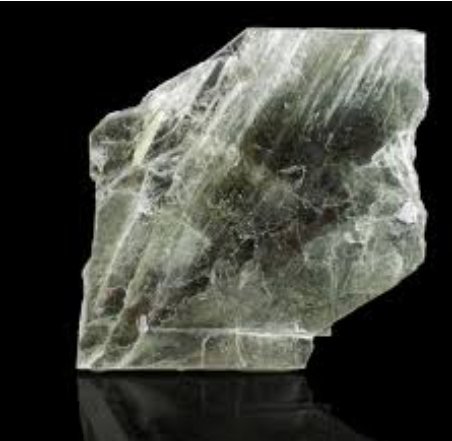

Mica is a group of silicate minerals known for their thin, flaky structure and ability to split into flexible and transparent sheets. Mica comes in several different forms, each with specific characteristics and applications. The most common types of mica are muscovite and phlogopite, but there are many other variants. These minerals are widely valued for their thermal stability, electrical insulation, and resistance to environmental stress.

Common Types of Mica

Mica can be classified into several types based on its physical and chemical properties. The most common types of mica are:

1. Muscovite Mica

Muscovite is the most abundant form of mica and is often referred to as “white mica.” It is known for its transparency and excellent dielectric strength, making it widely used in electrical insulators and electronics applications. It also has heat resistance up to 500°C, making it useful in high-temperature environments.

Applications of Muscovite Mica:

- Electrical and thermal insulation

- Capacitors

- Industrial heat shields

- Stove windows

2. Phlogopite Mica

Phlogopite, also known as “amber mica” or “brown mica,” is similar to muscovite but has a slightly lower dielectric strength. However, it can withstand much higher temperatures, up to 900°C, which makes it ideal for more extreme environments.

Applications of Phlogopite Mica:

- High-temperature insulators

- Foundry and furnace insulation

- Automotive components

- Flame retardant coatings

3. Biotite Mica

Biotite is a black or dark brown mica mineral often found in granite and metamorphic rocks. It is less commonly used in industrial applications due to its lower insulation properties but is still useful in specific applications requiring higher levels of heat resistance.

Applications of Biotite Mica:

- Geology and petrology studies

- Structural insulators in some specific applications

4. Lepidolite Mica

Lepidolite is known for its pinkish-purple color and is primarily used as a source of lithium in industrial applications. Although it is not as common as muscovite or phlogopite, lepidolite is gaining attention due to the rising demand for lithium-based batteries.

Applications of Lepidolite Mica:

- Lithium extraction for batteries

- Specialty ceramics and glass

- Decorative uses

5. Fuchsite Mica

Fuchsite is a green-colored mica variant rich in chromium. It is often used in decorative stone and jewelry but has limited industrial use. However, its stunning color and luster make it desirable in high-end applications.

Applications of Fuchsite Mica:

- Jewelry and decorative stones

- Metaphysical and healing stones

AUKI MICA, a leading mica products supplier, sources mica from Pakistan, Afghanistan, and other regions, transforming raw mica into high-quality finished products. Their product lineup serves various industries, including electronics, home appliances, and more.

Here are some of the popular mica products offered by AUKI MICA:

1. Mica Wave Plates

These are used in microwave ovens as they help distribute the waves evenly, ensuring even heating and preventing food from burning. Mica wave plates have excellent heat resistance and electrical insulation properties, making them a vital component in many appliances.

2. Stove Mica Windows

These transparent mica sheets are used in wood-burning stoves to provide a clear view of the fire while withstanding extreme heat. They are also used in other industrial applications requiring high temperature and thermal stability.

3. Mica Strainer Core

Mica strainer cores are used in filtration systems for high-temperature processes, where traditional materials may degrade. They help in ensuring smooth and efficient filtering operations under extreme conditions.

4. Silvered Mica Capacitor

Mica capacitors are widely used in radio frequency circuits due to their stability, low loss, and ability to handle high voltages. Silvered mica capacitors, in particular, offer enhanced electrical properties and durability, making them ideal for critical applications in electronics.

5. Incense Mica Plate

Mica plates are also used in the manufacturing of incense, where they provide a heat-resistant base that doesn’t burn. These plates are integral in ensuring safety and product longevity during the incense burning process.

How to Choose the Right Type of Mica

When selecting mica for a particular application, it’s crucial to understand the specific requirements of your project. Here are some key considerations:

1. Heat Resistance

Different types of mica offer varying levels of heat resistance. Phlogopite is ideal for high-temperature environments, while muscovite is better suited for moderate heat applications.

2. Electrical Insulation

For electrical applications, muscovite is the best choice due to its high dielectric strength. It is widely used in electronics, capacitors, and insulators.

3. Durability

Mica is inherently durable, but the specific type chosen will depend on the mechanical stresses and environmental conditions the material will face. Biotite and phlogopite may be better suited for heavy-duty or high-stress environments.

4. Size and Shape

Mica products can be customized into different shapes and sizes. AUKI MICA provides a variety of options, including mica sheets, discs, and custom shapes to fit the specific needs of your project.

5. Cost

Mica is generally an affordable material, but costs can vary based on the type and processing required. For example, silvered mica capacitors or incense mica plates may require additional manufacturing steps, which can impact the overall price.

Common FAQs about Mica

1. What are the primary uses of mica in the electronics industry?

Mica is commonly used in capacitors, insulators, and other electronic components due to its excellent electrical insulation and heat-resistant properties. Muscovite and phlogopite are the preferred types for these applications.

2. How is mica sourced?

Mica is typically mined from mica-rich deposits found in regions like Pakistan, Afghanistan, and India. After extraction, it is processed and refined for various industrial applications.

3. What makes mica so heat resistant?

Mica’s unique crystal structure allows it to withstand extremely high temperatures without breaking down. Phlogopite mica, in particular, can resist temperatures up to 900°C, making it suitable for demanding environments.

Table: Comparison of Common Mica Types

| Mica Type | Color | Temperature Resistance | Primary Applications | Special Features |

|---|---|---|---|---|

| Muscovite | Clear, White | Up to 500°C | Electrical insulators, capacitors, windows | High dielectric strength |

| Phlogopite | Amber, Brown | Up to 900°C | High-temp insulators, foundry uses | Excellent heat resistance |

| Biotite | Black, Dark Brown | Moderate | Geology, specific insulator uses | Low electrical insulation |

| Lepidolite | Pink, Purple | Moderate | Lithium extraction, specialty ceramics | Source of lithium |

| Fuchsite | Green | Moderate | Jewelry, decorative applications | High chromium content, aesthetic value |

Final Toughts

Mica plays a crucial role in various industries due to its versatile properties, such as heat resistance, electrical insulation, and durability. Whether you’re looking for mica wave plates for microwaves or silvered mica capacitors for electronics, AUKI MICA is a reliable supplier of high-quality mica products sourced from the best mines worldwide.

By understanding the different types of mica and their applications, you can make an informed decision that ensures the best performance for your project. Explore AUKI MICA’s product offerings today to find the perfect mica solution for your needs!