Introduction

White mica, also known as muscovite, is a mineral of great significance in various industries due to its unique properties. Its high thermal resistance, electrical insulation capabilities, and durability make it an essential component in a wide range of applications. From electronics to construction, white mica’s versatility is unmatched. This comprehensive guide will delve into the properties, processing, and uses of white mica, as well as the benefits of sourcing from reliable suppliers like AUKI MICA.

Table of Contents

- What is White Mica?

- Properties of White Mica

- Processing of White Mica

- Applications and Uses of White Mica

- Why Choose AUKI MICA?

- Frequently Asked Questions (FAQs)

- Comparison Table: White Mica vs. Other Types of Mica

- Conclusion

What is White Mica?

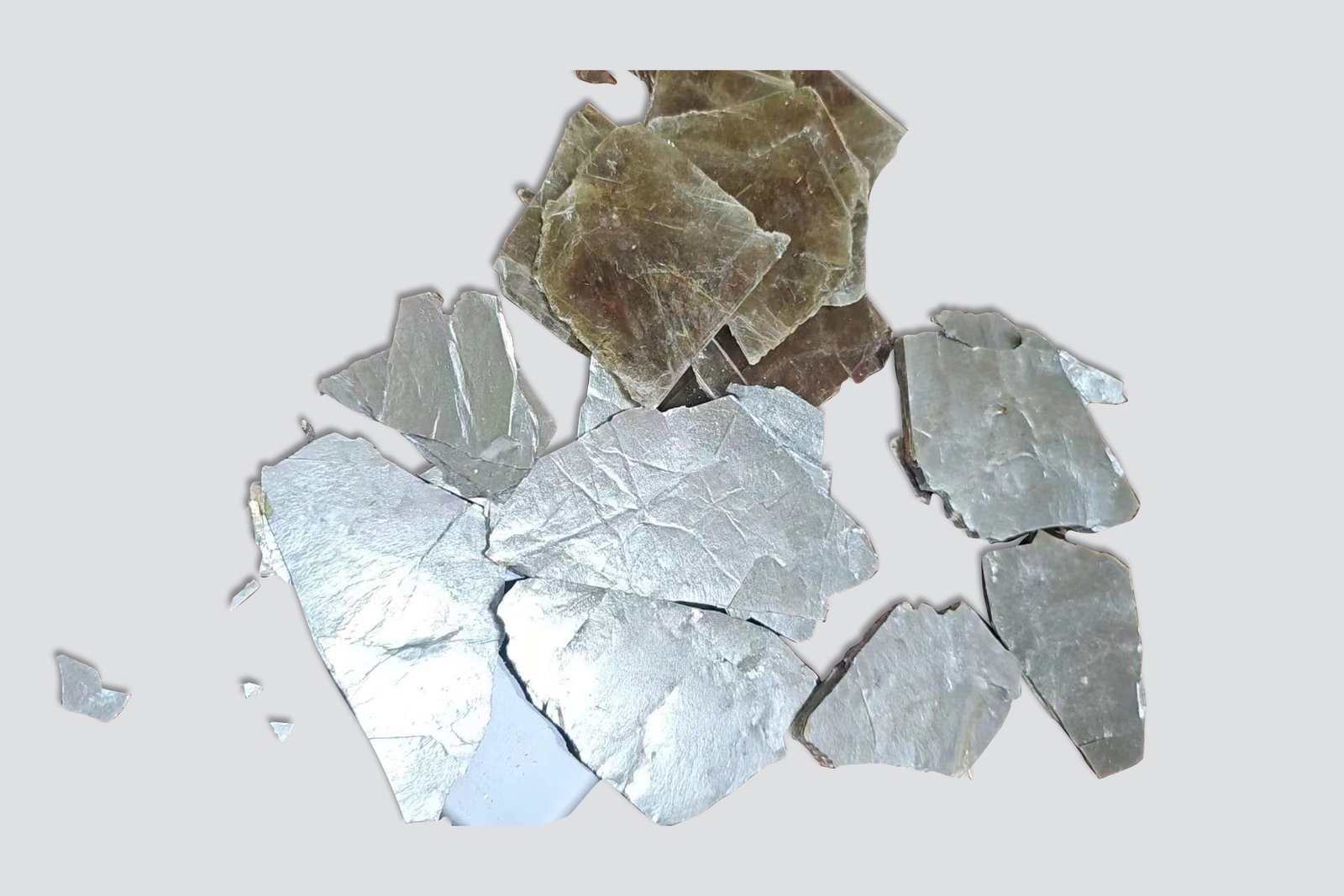

White mica, scientifically known as muscovite, is a member of the mica group of silicate minerals. It is characterized by its white, silvery sheen and is widely used due to its excellent thermal and electrical insulating properties. Found in metamorphic, igneous, and sedimentary rocks, white mica is abundant and can be sourced from various regions, including Pakistan, Afghanistan, Africa, and India.

Key Characteristics:

- Color: White, silvery, or pale-colored

- Transparency: Transparent to translucent

- Hardness: 2.5 – 3 on the Mohs scale

- Luster: Pearly to vitreous

- Cleavage: Perfect in one direction

Properties of White Mica

White mica is highly valued for its unique combination of properties, which include:

- Thermal Resistance: White mica can withstand high temperatures, making it ideal for use in high-temperature environments.

- Electrical Insulation: Its excellent dielectric properties make it a perfect material for electrical and electronic applications.

- Chemical Inertness: White mica is resistant to most acids and alkalis, contributing to its durability in various industrial processes.

- Flexibility and Elasticity: Despite its brittle appearance, white mica can be split into thin sheets that are both flexible and elastic.

- Optical Clarity: Its transparency is beneficial in applications where clarity is crucial, such as in gauge glasses.

Processing of White Mica

The journey of white mica from the mines to the final product involves several critical steps:

1. Mining

White mica is typically extracted from pegmatite veins or metamorphic rocks. AUKI MICA sources its white mica from reliable mines in Pakistan, Afghanistan, Africa, and India, ensuring high-quality raw material.

2. Sorting

Once extracted, the raw mica undergoes a strict sorting process to separate high-grade mica from impurities. This process is vital to ensure the quality of the final product.

3. Cutting and Splitting

The sorted mica is then cut into desired shapes and sizes. Its perfect cleavage allows it to be split into thin sheets without losing its integrity.

4. Processing into Products

The cut mica sheets are processed into various products such as gauge glass mica, mica washers, and mica discs, tailored to meet specific industrial needs.

Applications and Uses of White Mica

White mica’s versatility means it is used across a wide range of industries. Below are some of the primary applications:

1. Electrical Insulation

White mica’s excellent dielectric properties make it a staple in the electrical and electronics industries. It is used in:

- Mica Transistors: White mica is used as an insulating material in transistors due to its ability to withstand high voltages without breaking down.

- Mica Spacers: These are used in electrical appliances to prevent short circuits by maintaining a safe distance between conductive components.

2. Heat Resistance Applications

Due to its high thermal resistance, white mica is ideal for:

- Heat Shields: Used in furnaces and ovens to protect components from extreme heat.

- Mica Washers: These are often used in high-temperature environments as insulating components in machinery.

3. Construction Materials

In the construction industry, white mica is used for its insulating properties and durability:

- Mica Paper: Utilized as a lining material in construction for thermal insulation.

- Mica Discs: Used in various construction equipment for insulation purposes.

4. Cosmetic Industry

White mica’s pearlescent appearance makes it a popular ingredient in cosmetics:

- Makeup Products: Used in eyeshadows, highlighters, and nail polishes to provide a shimmering effect.

5. Automotive Industry

In the automotive industry, white mica is used for both its insulating properties and aesthetic appeal:

- Mica Sheets: Used in heat shields and insulating components in vehicles.

- Decorative Elements: The shimmering effect of white mica is also utilized in car paints and finishes.

6. Other Applications

White mica is also used in:

- Pharmaceuticals: As a filler in tablet coatings.

- Plastics and Rubber: As a reinforcing filler to improve mechanical properties.

Why Choose AUKI MICA?

AUKI MICA stands out as a leading supplier of high-quality mica products, offering tailored solutions to meet the diverse needs of industries worldwide. Here’s why you should consider AUKI MICA for your white mica requirements:

1. High-Quality Raw Materials

AUKI MICA sources white mica from the finest mines in Pakistan, Afghanistan, Africa, and India, ensuring that only the highest quality materials are used in their products.

2. Advanced Processing Techniques

With state-of-the-art processing facilities, AUKI MICA guarantees precision and consistency in the production of mica sheets, washers, discs, and other products.

3. Custom Solutions

AUKI MICA offers customized mica solutions tailored to the specific needs of each client, ensuring that their products meet the exact requirements of various industrial applications.

4. Global Reach

With a strong international presence, AUKI MICA can efficiently supply mica products to clients across the globe, ensuring timely delivery and excellent customer service.

Frequently Asked Questions (FAQs)

1. What are the main differences between white mica and other types of mica?

White mica, or muscovite, is primarily distinguished by its color, transparency, and superior electrical insulation properties. It is more stable at high temperatures compared to other types of mica, such as biotite or phlogopite.

2. How is white mica processed into final products?

White mica is first mined and then sorted to remove impurities. It is then cut and split into thin sheets, which are further processed into various forms like mica washers, discs, and papers according to industrial needs.

3. What industries benefit the most from using white mica?

White mica is extensively used in the electrical and electronics industries, construction, automotive manufacturing, and cosmetics due to its insulating properties, thermal resistance, and aesthetic appeal.

Comparison Table: White Mica vs. Other Types of Mica

| Property | White Mica (Muscovite) | Biotite | Phlogopite |

|---|---|---|---|

| Color | White, Silvery | Black, Dark Brown | Brown, Greenish |

| Thermal Resistance | High | Moderate | High |

| Electrical Insulation | Excellent | Poor | Good |

| Chemical Inertness | High | Moderate | High |

| Common Uses | Electrical, Heat Shields | Construction, Ceramics | High-Temp Insulation |

| Availability | Abundant | Less Abundant | Common in Specific Regions |

Final Toughts

White mica, or muscovite, is a vital mineral with extensive applications across various industries due to its unique combination of thermal resistance, electrical insulation, and chemical stability. Whether you’re in the electronics, construction, automotive, or cosmetics industry, white mica provides the performance and reliability needed for high-quality products.

When sourcing white mica, choosing a trusted supplier like AUKI MICA ensures you receive top-notch materials processed to meet your specific requirements. With high-quality raw materials, advanced processing techniques, and a commitment to custom solutions, AUKI MICA is well-positioned to be your go-to partner for all your mica needs.

Whether you’re looking for mica sheets, washers, discs, or custom solutions, AUKI MICA has the expertise and resources to deliver products that meet the highest standards of quality and performance.