Table of Contents

- Introduction

- Why Sight Glasses Matter

- 1. Standard Sight Glass (Alloy + Glass)

- 2. Threaded Oil Sight Window & Dome

- 3. Optical Level Gauge Type SNA (STAUFF)

- 4. Hydraulic Fluid Level Gauge (McMaster‑Carr)

- AUKI MICA: Gauge Glass Mica Supplier

- How to Choose the Right Sight Glass

- Summary Table

Introduction

Hydraulic tank sight glasses (also known as level gauges) are vital components of hydraulic systems, allowing operators to visually monitor fluid levels while ensuring system integrity. In 2025, advances in materials and design have made these gauges safer, more durable, and adaptable to harsh environments.

Why Sight Glasses Matter

- Prevent Over/Underfill: Enable precise fluid level monitoring

- System Health: Early indication of contamination or leaks

- Safety Compliance: Meets industrial standards and helps avoid damage

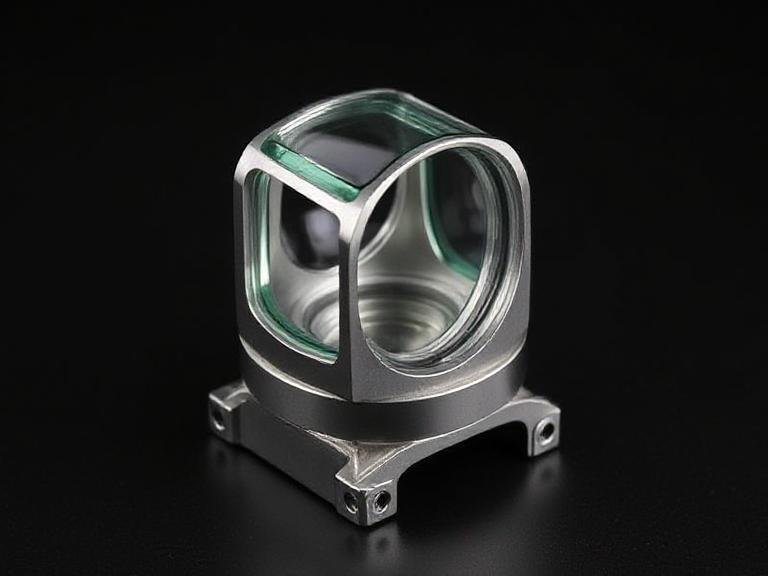

1. Standard Sight Glass (Alloy + Glass)

This basic model features a durable alloy or brass body with a glass or polycarbonate window. It is sealed for high-temperature and high-pressure environments.

- Versatile for oil, water, and hydraulic fluids

- Offers intuitive visual reading :contentReference[oaicite:1]{index=1}

- Cost-effective and widely available

2. Threaded Oil Sight Window & Dome

Manufacturers like Lenz offer threaded steel or stainless steel sight domes and windows with NPT or BSPP fittings.

- Tempered glass or polyamide lens up to 500 °F and 150 psi :contentReference[oaicite:2]{index=2}

- Durable metal housings ideal for industrial rigs

- Multiple materials and sealing options available

3. Optical Level Gauge Type SNA (STAUFF)

STAUFF’s SNA gauges use high-strength polyamide housings and glass tubes. They operate on a communicating- vessel principle.

- Available in lengths from 76 mm to 950 mm :contentReference[oaicite:3]{index=3}

- Rated for –30 °C to +80 °C, up to IP65 protection

- Optional thermometers, floats, and accessories

4. Hydraulic Fluid Level Gauge (McMaster‑Carr)

McMaster‑Carr stocks a range of hydraulic fluid sight gauges with various materials and pressure ratings.

- Bodies made from plastic, aluminum, stainless steel :contentReference[oaicite:4]{index=4}

- Options for high-pressure and sanitary applications

- Features include shut-off valves and high-pressure versions

AUKI MICA: Gauge Glass Mica Supplier

AUKI MICA specializes in natural mica products integral to high-end gauge windows, especially when added insulation and heat resistance are required.

- Owns mica mines in Pakistan, Afghanistan, Africa, and India

- Supplies gauge-glass-grade mica and mica washers, discs, windows

- Custom mica solutions tailored for sight glass manufacturing

How to Choose the Right Sight Glass

- Fluid Compatibility: Ensure chemical resistance of seals and glass

- Pressure/Temperature: Check rating meets system specs

- Mounting Type: Inline threaded vs. panel-mounted vs. domed

- Accessories: Thermometers, valves, guards, floats

- Durability: Metal body vs. plastic for rugged environments

Summary Table

| Type | Material | Key Features | Ideal Use Case |

|---|---|---|---|

| Standard Alloy + Glass | Alloy/Brass + Glass | Cost-effective, sealed for pressure | General hydraulic reservoirs |

| Threaded Dome/Window | Steel/Stainless + Tempered Glass | High-temp, threaded fit | Abrasive or high-temp fluids |

| STAUFF SNA Optical Gauge | Polyamide + Glass | IP65, modular, extended lengths | Industrial machinery, outdoor systems |

| McMaster-Carr Fluid Gauge | Plastic/Metal options | High-pressure, sanitary options | Sanitary, food, pharma, high-pressure use |

| AUKI MICA Mica Sheets | Natural mica | High temp/insulation window material | Manufacturers requiring insulating sight glass |