Table of Contents

- Introduction

- What Is Muscovite Mica?

- Understanding Cleavage vs. Fracture

- Cleavage Properties of Muscovite Mica

- Fracture Characteristics of Muscovite Mica

- Industrial Applications of Muscovite Based on Its Cleavage

- How AUKI MICA Delivers High-Quality Mica Products

- Product Range by AUKI MICA

- Choosing the Right Mica for Your Application

- Conclusion

- Summary Table

Introduction

Muscovite mica is a naturally occurring mineral prized for its exceptional cleavage, transparency, and heat resistance. It plays a critical role in electrical insulation, optics, and thermal applications. In this article, we explore whether muscovite mica is characterized more by cleavage or fracture, and how this determines its industrial utility.

What Is Muscovite Mica?

Muscovite is a type of mica belonging to the phyllosilicate group. It has a monoclinic crystal system and is composed primarily of potassium and aluminum silicate.

- Color: Colorless to pale brown

- Hardness: 2–2.5 on the Mohs scale

- Transparency: High optical clarity in thin sheets

- Common Forms: Flakes, sheets, or laminated structures

Because of its physical and chemical properties, muscovite is used in a variety of products such as electronics, thermal insulation, and precision optical devices.

Understanding Cleavage vs. Fracture

In mineralogy, both cleavage and fracture describe how a mineral breaks:

- Cleavage: The tendency of a mineral to break along flat, planar surfaces determined by its crystal structure.

- Fracture: The irregular or uneven way a mineral breaks when it does not cleave along defined planes.

The distinction is important in manufacturing because it impacts how the material behaves under mechanical stress and how it can be processed into finished products.

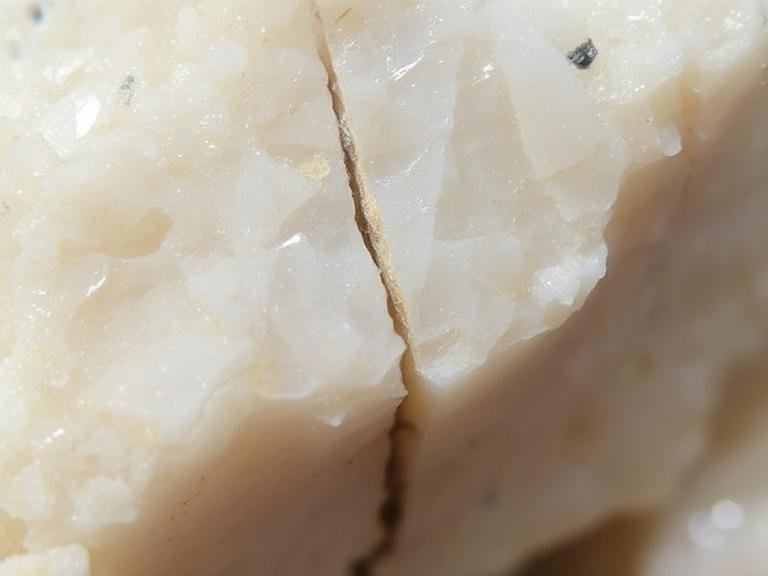

Cleavage Properties of Muscovite Mica

Muscovite mica is known for having perfect basal cleavage. This means it can be split into thin, uniform sheets along its base planes with great ease. Key characteristics include:

- One-directional cleavage: Occurs along the (001) plane

- Highly elastic sheets: Thin layers are flexible and can bend without breaking

- Optical clarity: Cleaved sheets remain transparent with a glossy finish

This perfect cleavage is what makes muscovite mica ideal for applications requiring flatness, dielectric integrity, and dimensional stability.

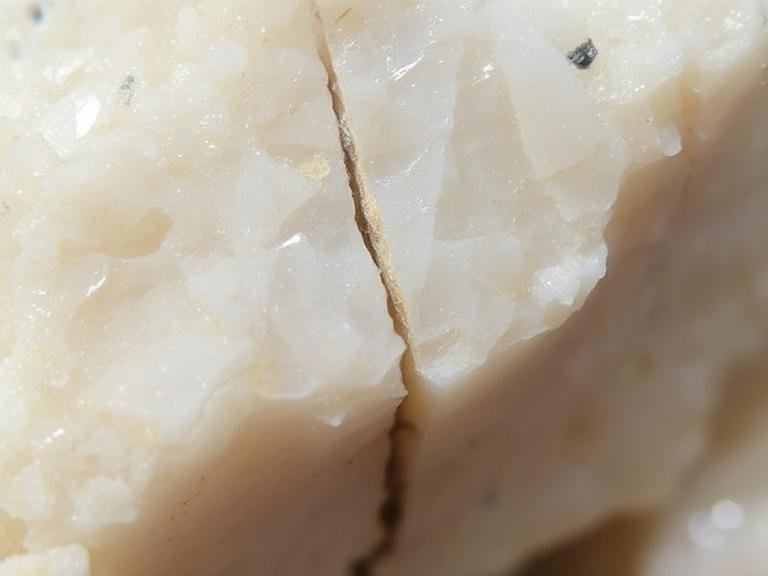

Fracture Characteristics of Muscovite Mica

While muscovite cleaves readily, in rare cases where cleavage is disrupted (due to impurities or structural damage), it may show a fracture pattern. However, this is not typical or desired in most industrial uses. If fractured, muscovite exhibits:

- Uneven fracture: Surfaces are jagged or splintered

- Brittle behavior: Fractured pieces can shatter easily

- Loss of function: Optical and insulating properties may be compromised

Manufacturers avoid fractured mica and rely on properly cleaved mica for precision applications.

Industrial Applications of Muscovite Based on Its Cleavage

The near-perfect cleavage of muscovite mica makes it suitable for diverse industrial purposes:

1. Electrical and Thermal Insulation

- Excellent dielectric strength

- Stable under high temperatures

- Used in transformers, capacitors, and electric motors

2. Optical and Scientific Instruments

- Clear mica sheets are used in optical wave plates

- Microscope slides and calibration optics

3. Stove and Heating Elements

- Transparent mica windows in wood stoves and heaters

- Withstands both heat and mechanical pressure

4. Mechanical Spacers and Washers

- Precision-cut from cleaved mica sheets

- Non-conductive and temperature-resistant

How AUKI MICA Delivers High-Quality Mica Products

AUKI MICA is a leading supplier of high-end mica insulating materials with a reliable global supply chain. Here’s how they ensure top-notch quality:

- Mine-to-factory control: Mica is sourced from company-owned mines in Pakistan and Afghanistan

- Strict material sorting: Only top-grade V1 muscovite is used for processing

- China-based processing: Final mica products are manufactured to global standards

- Custom solutions: AUKI offers tailored mica products to meet client specifications

Product Range by AUKI MICA

AUKI provides a variety of mica-based components that benefit from muscovite’s cleavage properties:

Choosing the Right Mica for Your Application

When selecting mica materials, especially muscovite, it’s important to assess the following:

- Application temperature: Choose mica that remains stable at required heat levels

- Thickness and flexibility: Based on how much stress or bending is involved

- Electrical performance: Critical for insulation and dielectric uses

- Cleavage quality: Uniform cleaving ensures better product consistency

AUKI MICA helps you navigate these considerations to provide optimal solutions that align with industrial, scientific, and electrical needs.

Conclusion

Muscovite mica is defined by its perfect basal cleavage, making it a versatile and essential material across various industries. Unlike minerals that fracture unpredictably, muscovite’s predictable, planar cleavage allows for precision shaping and reliable performance. Companies like AUKI MICA leverage their mining and processing capabilities to supply world-class mica components, ensuring quality, safety, and longevity in every application.

Summary Table

| Property | Details |

|---|---|

| Mineral Name | Muscovite Mica |

| Cleavage | Perfect basal (001) cleavage |

| Fracture | Rare; brittle and uneven |

| Applications | Insulators, optics, stoves, washers, spacers |

| Industrial Use | Thermal and electrical insulation, optical clarity |

| AUKI MICA Advantage | Own mines, strict sorting, custom mica solutions |

| Products | Gauge Glass, Mica Transistor, Disc, Washer, Lampshade Mica |